In the realms of technological innovation and scientific discovery, advanced materials hold a pivotal position, particularly in industries where performance and efficiency are paramount. Among these industries, aerospace stands at the forefront, continually pushing the boundaries of what is possible through the ingenious application of these materials. The marriage of strength and lightness in advanced materials is not just an advantage but a necessity, making the exploration of such materials a fascinating and crucial endeavor.

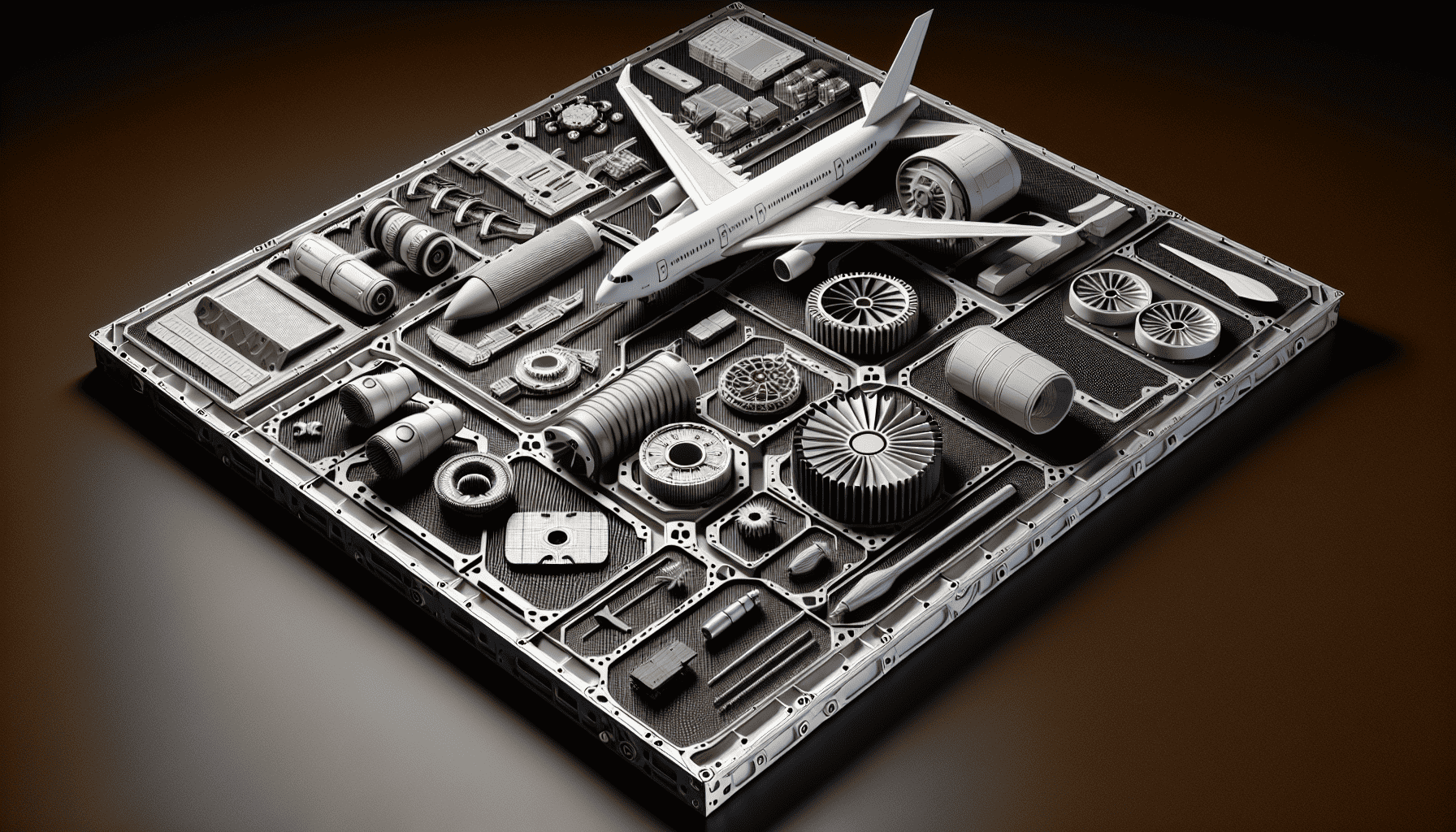

The aerospace industry is characterized by its ever-demanding requirements for materials that can perform under extreme conditions while minimizing weight to enhance fuel efficiency. The shift towards advanced materials in aerospace engineering is driven by this delicate balance of strength and lightness. Materials such as carbon fiber composites, titanium alloys, and ultra-high-temperature ceramics have become cornerstones of modern aerospace design. Each of these materials offers unique properties that contribute to their wide array of applications.

Carbon fiber composites, for instance, are renowned for their exceptional strength-to-weight ratio. This makes them ideal for constructing aircraft structures that need to withstand high loads while maintaining a lightweight profile. Carbon fibers are made from extremely thin strands of carbon atoms bonded in a crystalline formation, which gives them their strength. When these fibers are embedded in a polymer matrix, they form composites that are both strong and flexible. As a result, they are extensively used in manufacturing aircraft components such as wings, tail sections, and fuselage panels.

Titanium alloys are another critical class of materials in aerospace advancements. Known for their high strength, resistance to extreme temperatures, and corrosion resistance, titanium alloys are essential in engine components, landing gear, and airframes. These alloys can withstand the high stress and heat generated during flight, maintaining structural integrity and reliability over time. The relatively low density of titanium compared to traditional metals like steel further enhances its appeal, contributing to overall weight reduction in aircraft.

In the realm of advanced ceramics, ultra-high-temperature ceramics (UHTCs) offer promising solutions for spacecraft and supersonic aircraft. These materials can endure temperatures exceeding 2000 degrees Celsius, making them well-suited for thermal protection systems in space vehicles re-entering Earth's atmosphere or in leading edges of hypersonic aircraft. Their ability to maintain stability and resist oxidation under such extreme heat conditions ensures the safety and effectiveness of aerospace missions.

The development of advanced materials is not confined to current technologies. Ongoing research in nanotechnology and metamaterials promises to unlock new potentials in aerospace design. Nanocomposites, which incorporate nanoscale materials into a matrix, can enhance mechanical, thermal, and electrical properties, leading to lighter and more multifunctional components. Metamaterials, engineered to have properties not found in naturally occurring materials, offer possibilities such as negative refractive indices for advanced stealth capabilities or improved insulating properties.

The pursuit of advanced materials in aerospace is not merely an exercise in material science but a crucial effort to address broader challenges such as environmental sustainability and economic efficiency. Reducing the weight of aircraft and spacecraft translates directly into lower fuel consumption and reduced greenhouse gas emissions. Moreover, the extended lifespan and performance reliability of these materials can result in significant cost savings over time.

In conclusion, the continuous evolution of advanced materials is imperative to meet the ever-growing demands of the aerospace industry. By harmonizing strength with lightness, these materials are reshaping the future of aerospace engineering, enabling more efficient, safer, and environmentally-friendly flight. As research progresses, the impact of these materials is set to expand, fostering innovations that will redefine the possibilities of flight and space exploration.